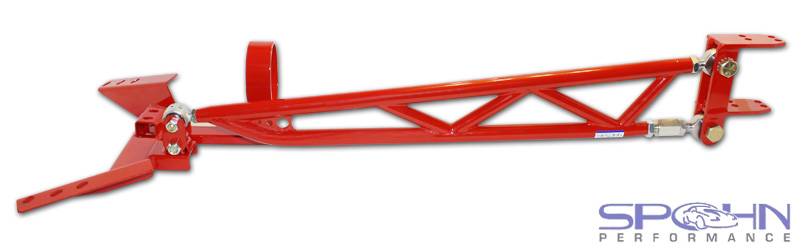

82-92 Fbody Spohn Performance Pro-Series Adjustable Torque Arm – 200-4R Transmission

$629.00 – $691.50

Model Number: 307-PSWhat is the difference between the standard crossmember mounted torque arms and the Pro-Series crossmember mounted torque arms? Click Here to find out the differences.

Spohn Pro-Series torque arms are the strongest and hardest hooking torque arms on the market. This kit is for installing a 200-4R transmission into a Third Generation F-Body. The kit includes the transmission crossmember required to install the 200-4R transmission, along with the crossmember mounted Pro-Series adjustable torque arm. The 200-4R transmission has no provisions to mount the OEM torque arm onto the transmission tailshaft. The kit makes the 200-4R swap an easy bolt right in installation!

If you need bullet-proof strength, serious performance, improved handling, and pavement digging traction when you’re at the dragstrip, AutoX, or road racing; then you need a Spohn Performance Pro-Series torque arm, here’s what it’ll do:

- Attaches to the rear axle and controls rear end torque during acceleration, transferring this energy into the tires, increasing straight line traction

- Reduces nose-dive during braking

- Eliminates wheelhop

- Increases sidebite during corner exit acceleration

- Bolt-on system does not require complete interior removal as with other kits

- No fabrication, welding or drilling required – 100% bolt-in installation!

- Removes the torque arm pivot point from the rear of the transmission to the supplied crossmember

- Changes the instantaneous center and leverage point from stock

- Provides adjustable pinion angle

- FREE angle finder included to set pinion angle

Build Specifications:

Spohn offers the option of getting your torque arm with a front driveshaft safety loop: NHRA rules call for a front driveshaft safety loop to prevent catapulting of the vehicle in the event of a front u-joint or driveshaft failure. Protect yourself, and your investment, and play it safe by containing the front of the driveline.

| Weight | 1 oz |

|---|---|

| Front Mount Type | Chrome Moly Spherical Rod End, Del-Sphere Pivot Joint, Polyurethane Bushing |

| Driveshaft Loop? | |

| Rear-End | |

| Color |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.